Mô tả

In the steel industry, steel transportation logistics is considered a critical step that determines the quality of materials delivered to businesses and construction projects. Steel is a product with heavy weight, bulky dimensions, and sensitivity to environmental factors. Even a small mistake during transport can lead to warping, rusting, or loss. This not only increases costs but also delays project schedules.

So how can businesses optimize steel transportation logistics to be cost-effective while minimizing risks? In this article, CCN Vietnam shares practical experience, analyzes the characteristics of steel transport, and introduces strategies for businesses to confidently implement logistics operations without worry.

1. Characteristics of Steel Transportation

To understand why steel transportation logistics requires strict processes, we need to look at the properties of each type of steel and the factors affecting transportation. Understanding these characteristics allows businesses to organize cargo properly, select suitable transport methods, and plan logistics efficiently, thereby saving costs and reducing risks.

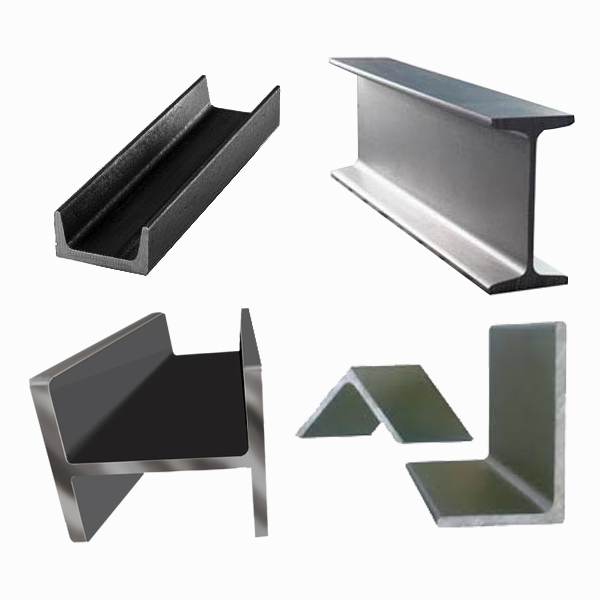

Steel is an extremely heavy material, with some orders reaching hundreds or even thousands of tons. Additionally, steel comes in various sizes: long and wide plates, H-I-U profiles with angular structures, hollow pipes that can roll during movement, and coils weighing several tons. Steel is also prone to rust when exposed to rain or humidity, which directly impacts quality upon use.

Improper loading or handling can easily lead to deformation or warping. Therefore, steel transportation logistics always requires professional handling, standardized warehouses, and skilled operators. These characteristics make steel transport a highly specialized field demanding strict procedures and technical expertise.

2. Methods of Steel Transportation

To optimize steel transportation logistics, businesses need to choose transport methods that match their specific needs. Each method has advantages and disadvantages that directly affect transport costs. Understanding these differences allows businesses to plan efficient, cost-saving steel deliveries.

|

Method |

Advantages |

Disadvantages |

Suitable For |

|

Road (trucks, containers) |

Flexible, fast delivery, schedule control |

Limited load, traffic congestion |

Domestic <500 km |

|

Rail |

Can carry large volumes, stable |

Fixed schedule, less flexible |

North–South shipments |

|

Sea |

Low cost for large shipments |

Long transit time, port-dependent |

Import-export steel |

|

Air |

Fastest |

Very expensive |

Steel samples, urgent components |

For each shipment, businesses can consider volume, delivery time, and cost to choose the optimal method. Particularly for large-scale steel shipments, rail and sea transport are usually the most cost-effective options.

3. Common Risks in Steel Transportation

Understanding potential risks allows businesses to implement preventive measures before executing steel transportation logistics. These risks often arise from environmental factors, transport methods, or handling errors.

Common risks include:

- Warping or deformation due to improper stacking

- Rust when steel contacts rain or high humidity

- Loss or misplacement during large-volume deliveries

- Increased costs due to non-optimal routes or transport methods

Recognizing these risks is essential for ensuring smooth, efficient, and cost-effective steel logistics operations.

4. Strategies to Reduce Costs & Risks in Steel Logistics

To achieve optimal efficiency in steel transportation logistics, businesses should apply multiple strategies simultaneously, from packaging to route management. These best practices have been successfully implemented by many industry players.

1. Choose a Steel-Specialized Logistics Provider

Partnering with a logistics provider experienced in steel transportation logistics saves time and reduces risk. The provider should have:

- Nationwide steel transport experience

- Trucks, trailers, containers, and standardized warehouses

- Ability to handle issues arising from heavy cargo transport

2. Optimize Packaging & Handling

Each type of steel requires proper packaging and stacking standards to ensure safety during transport:

- Steel plates: stacked in layers with wooden spacers to prevent warping

- Steel pipes: securely bundled with anti-rolling supports

- Steel coils: placed horizontally with fixed frame restraints

Proper packaging and handling are critical to minimizing damage during steel transport.

3. Plan Efficient Routes

Optimized routes significantly reduce costs. Key considerations include:

- Avoiding congested roads or multiple checkpoints

- Avoiding weak-load bridges for safety

- Combining multiple shipments on the same route to lower costs

4. Apply GPS Tracking Technology

Modern steel transportation logistics increasingly relies on GPS:

- Real-time monitoring of transport routes

- Reduces risk of lost or misplaced cargo

- Allows rapid response to incidents or route adjustments

5. Insure Steel Cargo

For large shipments, insurance is essential:

- Compensates for damage or loss

- Ensures business protection for both domestic and international transport

6. Clear Logistics Contracts

A detailed logistics contract prevents disputes during transport:

- Clearly defines costs

- Specifies delivery schedules

- Details responsibilities of both parties in case of incidents

5. The Role of Warehouses in Steel Logistics

Standardized warehouses are the foundation of safe and efficient steel transportation logistics. A professional steel warehouse should provide:

- Spacious, well-ventilated, moisture-resistant storage

- Forklifts and cranes specialized for heavy steel

- Separate zones for different steel types

High-quality warehouses not only protect steel but also optimize storage costs for businesses.

FAQ – Frequently Asked Questions

1. Which transport method is best for North–South steel shipments?

For large volumes without urgent delivery requirements, rail or sea is optimal due to lower costs and higher capacity. These are suitable for nationwide steel transportation logistics.

2. Which ports are commonly used for imported steel from Japan and China?

Most imported steel arrives at major ports such as Cai Mep – Thi Vai, Hai Phong, or Cat Lai before distribution. These ports have modern loading systems suitable for large-scale steel shipments.

3. Is insurance necessary for domestic steel transport?

Yes, particularly for shipments over 500 tons or high-value cargo. Insurance reduces risk from damage or loss, ensuring safety for steel transportation logistics.

Conclusion: Optimize Steel Transportation Logistics to Reduce Costs and Risks

Steel transportation logistics is a crucial link affecting project timelines and quality. Choosing the right transport method, optimizing packaging, monitoring routes, and managing warehouses effectively can significantly reduce costs and nearly eliminate risks. Investing in professional logistics solutions is a sustainable approach for every business in the steel industry.

CCN Vietnam is ready to support your business with comprehensive steel logistics services: standardized warehouses, specialized vehicles, 24/7 GPS tracking, and competitive shipping rates. Contact us today for expert advice and the best quotes for your projects.

.png)

.jpg)

-480x320.jpg)