Mô tả

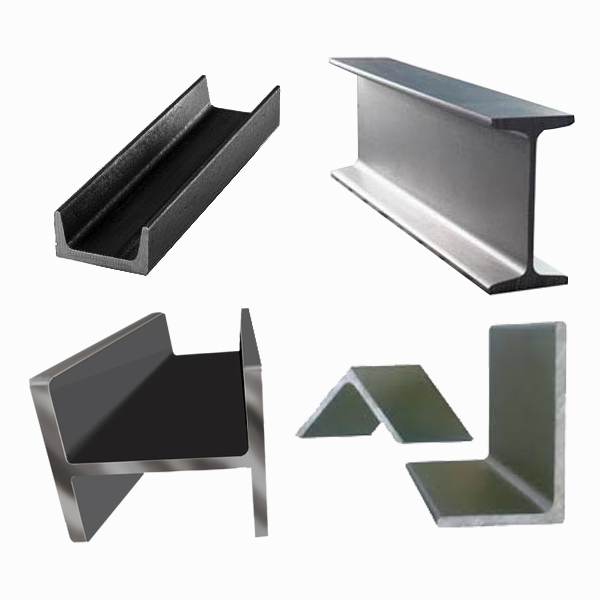

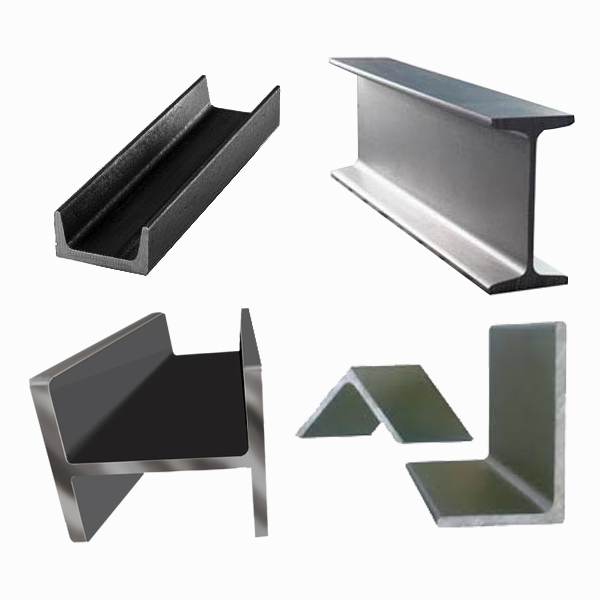

Overview of Steel Shapes

Steel shapes such as V steel, U steel, I steel, and H steel form the backbone of construction and industrial projects. They play critical roles in load-bearing, creating strong connections, and defining structural frameworks for factories, bridges, and residential buildings. Understanding the general characteristics, advantages, and load-bearing capabilities of these steel profiles helps engineers select the right steel type, ensuring efficiency and cost savings.

Common Features of Steel Shapes

Steel shapes are manufactured according to TCVN, JIS, or ASTM standards, ensuring high durability and precise tolerances. They feature cross-sections shaped like V, U, I, or H, which evenly distribute forces, bear heavy loads, and allow for easy assembly. Steel surfaces can be galvanized or coated with anti-corrosion paint to increase lifespan and reduce maintenance costs.

Advantages in Steel Structures

V steel, U steel, I steel, and H steel all offer excellent load-bearing capacity, easy installation, design flexibility, and material efficiency. They are suitable for a wide range of projects, from prefabricated steel buildings and factories to bridges. High production standards help prevent deformation, increase frame stability, and reduce construction risks.

V Steel (V50 – V200)

V steel features a characteristic V-shaped cross-section, excelling in longitudinal load-bearing and versatile applications in light to medium structures.

Structure & Technical Specifications

V steel has a V-shaped profile, with standard sizes ranging from V50 to V200. The side length and thickness are designed according to JIS or TCVN standards, ensuring adequate tensile strength and compression resistance. V steel is commonly used for light connections, bracing, purlins, and elements requiring moderate load capacity.

Load Capacity & Applications

V steel provides excellent longitudinal load-bearing and limits deformation, enhancing stability for small and medium structures. Typical applications include residential buildings, roof structures, purlin frameworks, and light industrial suspension systems. Its simple design and relatively light weight make V steel flexible and easy to install.

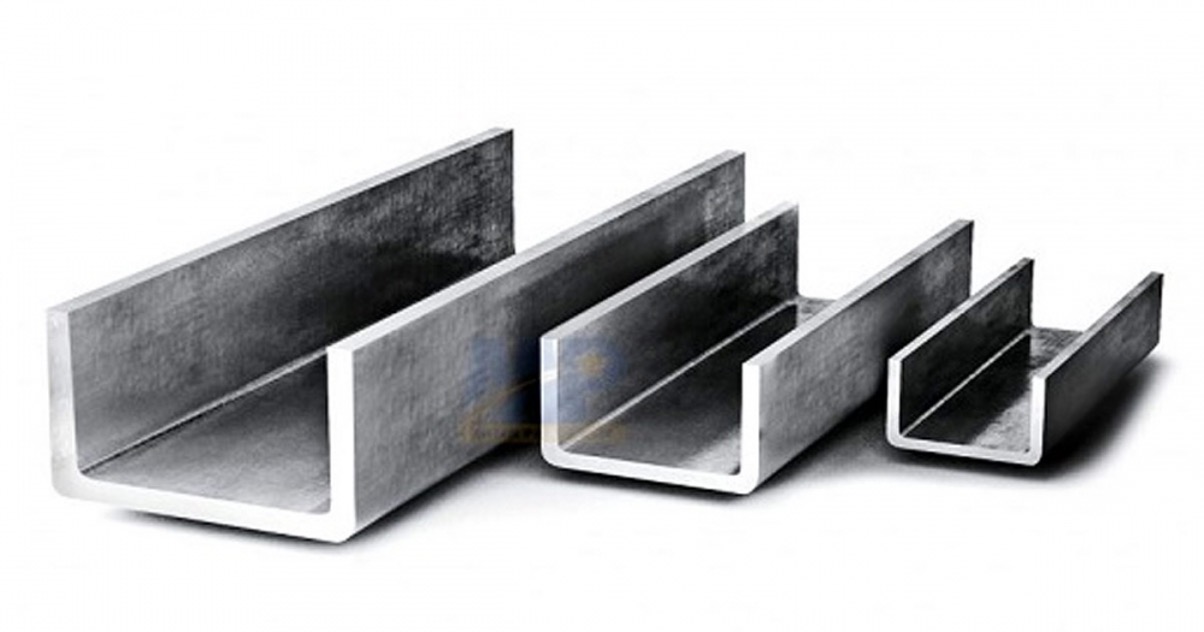

U Steel – Features & Application Scope

U steel is recognized for its ability to bear loads both horizontally and vertically, making it ideal for frames, bridges, and industrial structures.

Horizontal & Vertical Load Capacity

With a U-shaped cross-section, U steel distributes forces evenly and withstands both horizontal and vertical loads, minimizing bending and deformation. The flange height and web thickness are designed to handle heavy loads, meeting civil and industrial structural requirements.

Applications in Civil & Industrial Projects

U steel is widely used in factories, bridges, steel frame structures, and medium to heavy load-bearing projects. It is suitable for roof frameworks, tension braces, and anti-vibration systems. Its flexible installation helps shorten construction time and reduce material costs.

I Steel – Popular Choice for Large Structures

I steel, with its I-shaped cross-section, is the optimal choice for large structures due to exceptional rigidity and load-bearing capacity.

Key Specifications (I100 – I900)

I steel ranges from I100 to I900, with standardized web height and flange width. It offers excellent bending strength and tensile resistance, suitable for beams, columns, and floors carrying heavy loads. Common materials include SS400, Q235, or Q345 steel, ensuring durability and long service life.

Applications in Prefabricated Steel Buildings, Beams, and Floors

I steel is used in prefabricated steel buildings, bridge beams, industrial floors, and other heavy-load structures. Its I-shaped design distributes forces evenly while reducing steel weight compared to equivalent load-bearing alternatives, making I steel a popular choice in modern industrial and residential construction.

H Steel – The “King of Heavy Structures”

H steel, featuring an H-shaped cross-section, is renowned for high rigidity, stability, and exceptional load-bearing capacity, ideal for industrial and large-scale infrastructure projects.

H200 – H900: High Rigidity & Stability

H steel has a balanced H-shaped profile, optimizing rigidity between flanges and web. Sizes range from H200 to H900, with thick flanges and webs to withstand heavy loads, resist bending, and minimize deformation. H steel is the top choice for bridges, industrial buildings, and ports.

Applications in Factories, Bridges, and Ports

H steel is commonly used in industrial factories, bridges, warehouses, and heavy-load structures. Its H-shaped design evenly distributes forces, increases structural stability, reduces maintenance costs, and prolongs project lifespan.

Comparison Table of V Steel – U Steel – I Steel – H Steel

A comparison table evaluates durability, weight, and cost of V steel, U steel, I steel, and H steel to help select the right steel for each project.

Strength Comparison

H and I steel have higher bending and load-bearing strength than V and U steel, suitable for heavy structures and bridges. V and U steel are ideal for light to medium structures, with advantages in ease of fabrication and quick installation.

Weight Comparison

V steel is the lightest, followed by U, I, and H steel being the heaviest. Steel weight directly impacts transportation, installation, and structural load.

Cost Comparison

V and U steel are more affordable, suitable for small to medium projects. I and H steel are more expensive but offer higher load-bearing capacity, reduce additional material use, and optimize safety.

How to Choose the Right Steel Shape for Your Project

Choosing between V steel, U steel, I steel, and H steel should consider load, technical requirements, and project type to ensure efficient construction and long-term safety.

Select Based on Load

- Light load: V or U steel

- Heavy load: I or H steel

- For prefabricated steel buildings, bridges, beams, and heavy floors: I or H steel is optimal

Select Based on Technical Requirements

Consider load-bearing capacity, rigidity, tolerance, and technical standards. Always choose reputable suppliers with CO, CQ certificates, tensile and bending tests to ensure high-quality steel suitable for long-term projects.

Which Steel Shape Is Optimal Today?

Each steel profile (V, U, I, H) has its own advantages depending on project type, load, and technical requirements. For light to medium structures, V and U steel are cost-effective. For heavy structures, large-scale construction, or bridges, I and H steel offer superior strength, stability, and efficiency. Selecting the right steel ensures safety, cost savings, and longevity of the project.

Contact CCN Vietnam today for detailed consultation, transparent pricing, and expert guidance to choose the right V steel, U steel, I steel, or H steel for your project!

.png)

-480x320.jpg)