Mô tả

In today’s construction industry, accurately calculating steel weight and cost is a crucial step to ensure that the project budget remains under control. Steel accounts for a large portion of total material costs, making it essential to know precisely how much steel is required. This helps investors optimize cash flow and minimize waste during construction. However, not everyone understands how to apply formulas for steel plate weight, structural steel (H/I/U/V), steel pipes, or rebar coils to determine the correct numbers.

This guide, prepared by CCN Vietnam, provides a complete and easy-to-follow explanation to help you calculate steel weight and cost for all types of structures. With standard formulas, practical examples, and expert insights, you can perform your own material calculations without depending entirely on contractors.

1. Why You Should Calculate Steel Weight Before Construction

Determining steel weight accurately before construction allows businesses to control their budgets and avoid unexpected expenses. When investors know the exact amount of steel they need, they can plan their purchasing schedule more effectively, optimizing cash flow at every stage. This is a key factor in maintaining smooth project operations and avoiding excessive stock.

Calculating steel weight also ensures that the construction schedule remains on track. If steel is under-ordered, the project may be delayed while waiting for additional material. On the other hand, ordering too much steel increases storage and transportation costs unnecessarily. Therefore, having an accurate steel weight calculation helps ensure that construction proceeds according to plan.

Additionally, early calculation prevents material waste—one of the main reasons why project budgets often escalate. With the correct steel weight determined from the start, businesses use only the exact amount specified in the design, reducing losses and improving investment efficiency.

Once you understand the importance of calculating steel weight and cost, the next step is mastering the formulas used for each type of steel. Since every steel product has a different method of calculation, knowing these formulas ensures maximum accuracy.

2. Steel Weight Calculation Formulas

1. Hot-Rolled & Cold-Rolled Steel Plates

For steel plates, the weight formula is simple and widely used in mechanical, manufacturing, and construction projects. The standard formula is:

Weight (kg) = Length (m) × Width (m) × Thickness (mm) × 7.85

Example:

A steel plate measuring 6m × 2m with a 10mm thickness:

6 × 2 × 10 × 7.85 = 942 kg

This standard value follows ASTM and JIS specifications, making it easy for businesses to convert weight for ordering or cost estimation.

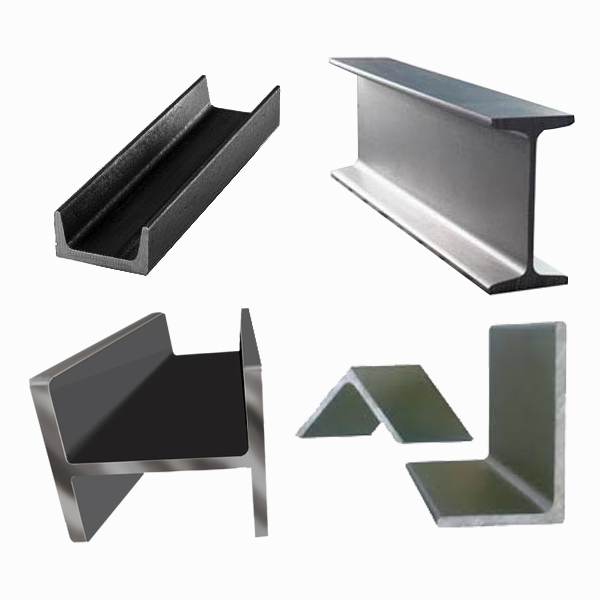

2. Structural Steel H, I, U, V

Structural steel has a more complex shape, so weight is determined using international standard tables such as those from JIS or ASTM.

Example:

H-beam H200×200×8×12 weighs 49.9 kg/m according to JIS.

For a 12m beam:

49.9 × 12 = 598.8 kg

Using standard tables ensures accuracy and consistency across applications. This is also the preferred method for contractors when estimating weight from structural drawings.

3. Steel Pipes (Welded & Seamless)

Steel pipes use a specialized calculation based on diameter and wall thickness.

Weight (kg/m) = 0.02466 × (Outer diameter – Thickness) × Thickness

Example:

Steel pipe D114 with 4mm thickness:

0.02466 × (114 – 4) × 4 = 10.8 kg/m

This formula applies to both seamless and welded pipes, allowing quick calculation even without a detailed catalog.

4. Round Bar & Steel Coils

For round rebar or coils, the formula is based on diameter:

Weight (kg/m) = Diameter² × 0.006165

Example:

Rebar Ø16:

16² × 0.006165 = 1.58 kg/m

For a 12m bar:

1.58 × 12 = 18.96 kg

This formula is especially important in residential construction where sizes like D10, D12, and D16 are commonly used.

3. How to Calculate Steel Cost in Construction

To calculate the material cost for a project, simply multiply steel weight by the supplier’s unit price:

Steel Cost = Steel Weight × Price per kg

Example:

If you have 5 tons of hot-rolled steel plates with a price of 15,500 VND/kg:

5,000 × 15,500 = 77,500,000 VND

Once you have design drawings and steel quantity tables, you can estimate the budget at the earliest stage without waiting for contractor quotations.

4. Tools to Help Calculate Steel Weight & Cost

Today, many tools assist investors and engineers in performing accurate steel calculations:

- International standard tables (JIS, ASTM, DIN)

- Pre-built Excel files with formulas

- Construction estimation software (G8, Delta, Etabs)

- Professional consultation from reliable suppliers like CCN Vietnam

These tools help minimize errors and improve the accuracy of both steel selection and cost estimation.

5. Tips to Save Steel Costs in Construction Projects

To optimize your budget, comparing prices across multiple suppliers is essential—especially since steel prices fluctuate frequently. Buyers must also select the correct steel grade according to design requirements to avoid unnecessary expenses.

Purchasing from authorized distributors helps eliminate hidden costs such as shipping fees, incorrect specifications, or risks related to low-quality steel. Additionally, planning purchases in stages reduces financial pressure and prevents excessive storage.

FAQ – Frequently Asked Questions

1. How can I quickly calculate steel plate weight?

The simplest method is using the formula Length × Width × Thickness × 7.85. For those unfamiliar with calculations, pre-built Excel sheets also provide fast and accurate results.

2. Do steel price fluctuations significantly affect project cost?

Yes. Steel accounts for 20–30% of total material costs, so any price change directly impacts the investor’s budget and the project timeline.

3. Should I buy extra steel beyond what the design requires?

Purchasing an extra 2–3% is reasonable to avoid shortages during construction. However, buying too much may cause storage, waste, and additional transportation costs.

Conclusion

Accurately calculating steel weight and cost is a foundational step that ensures smooth, cost-effective, and efficient construction. With standard formulas, steel reference tables, and modern calculation tools, you can confidently estimate all types of steel including hot-rolled plates, structural steel beams, steel pipes, and steel coils.

If you need further support with cost estimation or updated steel pricing, contact CCN Vietnam - your trusted distributor of industrial and construction steel with competitive prices and professional consulting.

.png)

-480x320.jpg)