Mô tả

In modern construction, steel materials account for a significant portion of total project expenses—approximately 30–40% of the material budget. Choosing the right type of steel not only ensures structural quality but also helps investors save substantial costs. Many contractors and project owners struggle with deciding whether to use steel plates, structural steel, or steel pipes for different components.

This article provides a comprehensive guide on optimizing the selection of steel materials, covering essential principles, common steel types, accurate quantity calculations, and cost-saving solutions. With the right approach, businesses can enhance safety, extend the lifespan of their structures, and optimize overall investment costs.

1. Principles for Selecting Steel to Optimize Costs

When choosing steel materials for a project, the most important principle is selecting the correct type. Each structural application requires a suitable steel category: steel plates for bridges and roads, structural steel for high-rise frameworks, and steel pipes for scaffolding or pipelines. Choosing the wrong type can lead to waste and reduced performance.

Steel standards are equally critical. Using steel certified under ASTM, JIS, or TCVN ensures proper load-bearing capacity, durability, and corrosion resistance. Non-standard steel may cause structural failures and significantly increase long-term repair costs.

The required quantity of steel must be calculated carefully. Overstocking wastes storage space and budget, while underestimating demand can delay construction progress and create unexpected expenses.

Finally, choosing a reputable supplier plays a crucial role in both quality and cost efficiency. Nationwide distributors with clear mill certificates and reliable logistics services help minimize risks of counterfeit steel and reduce transportation or handling costs.

2. Common Types of Steel and When to Use Them

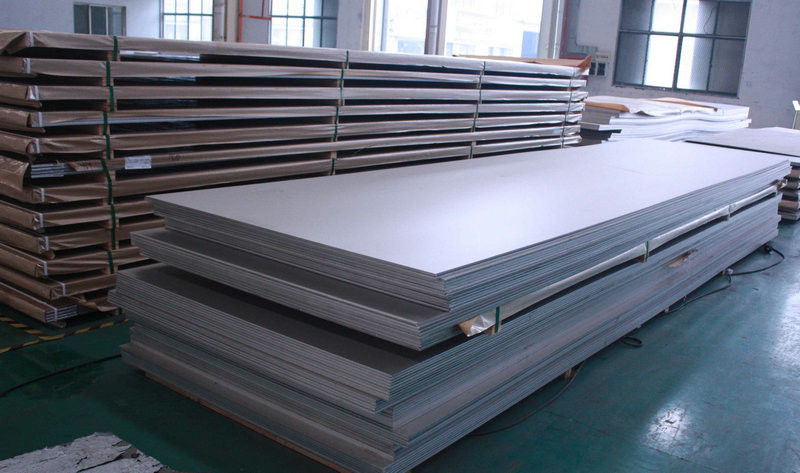

Hot-Rolled Steel Plates

Hot-rolled steel plates stand out for their excellent load-bearing capacity and ease of fabrication. They are commonly used in bridges, industrial warehouses, and storage tanks. Thanks to their thickness and durability, steel plates support heavy-load structures effectively. Choosing the correct thickness and dimensions ensures material savings while maintaining structural safety.

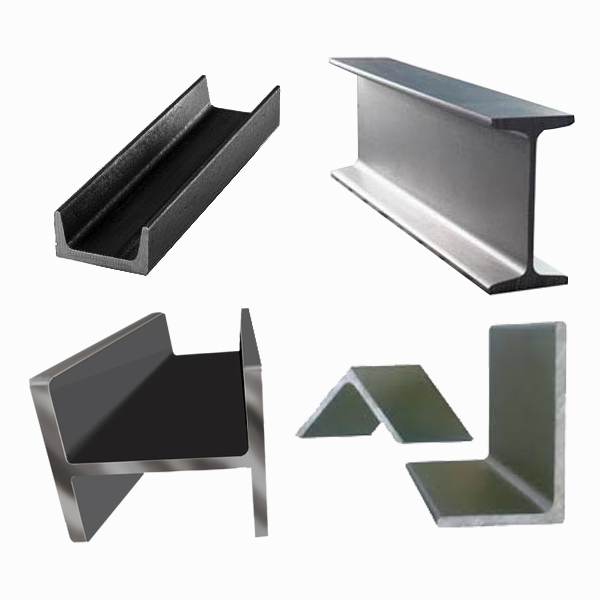

H- and I-Shaped Structural Steel

H-beam and I-beam steel are known for high rigidity, making them ideal for large structures such as high-rise buildings, crane beams, and pre-engineered steel frames. Their resistance to bending and deformation helps maintain structural stability under heavy loads. Using the correct standard of structural steel reduces welding points and cuts down auxiliary materials, thereby lowering construction costs.

Steel Pipes (Seamless and Welded)

Steel pipes are lightweight, easy to transport, and help reduce material volume in scaffolding, pipeline systems, and industrial frameworks. Contractors should pay attention to pipe diameter, wall thickness, and steel grade to ensure technical requirements while avoiding unnecessary material waste. Their lightweight characteristics also speed up installation and reduce labor costs.

Galvanized Steel

Galvanized steel is favored for its exceptional corrosion resistance and long lifespan, especially in outdoor structures or telecommunications infrastructure. The zinc coating forms a protective layer that shields the steel from harsh weather and oxidation. Using galvanized steel for poles, guardrails, and bridge structures reduces long-term maintenance costs and increases investment efficiency.

3. How to Calculate Steel Requirements Accurately

Accurate calculation of steel materials is essential for cost optimization. Contractors should start by using weight tables for steel plates, structural steel, and steel pipes to estimate quantities needed for each component.

Modern software like BIM (Building Information Modeling) provides precise calculations and minimizes the risk of over- or under-ordering steel. BIM also assists with installation planning, progress tracking, and material placement management.

Additionally, working closely with structural engineers to review design plans before placing orders ensures accurate steel volume calculations. This reduces waste and helps contractors optimize their material budget.

4. Cost-Saving Solutions When Purchasing Steel

To save costs, contractors should compare quotes from multiple suppliers to determine the best option. Negotiating discounts for bulk purchases can also significantly reduce total project expenditures.

A strategic combination of direct imports and domestic purchases helps optimize costs. Imported steel may benefit from FTA tariff incentives, while domestic steel reduces transportation costs and delivery times.

Equally important is choosing steel with transparent mill certificates to avoid counterfeit or substandard products. This ensures construction durability and prevents additional repair or replacement costs.

5. The Role of Suppliers in Cost Optimization

A reputable supplier offers more than just products. They provide expert advice on selecting the most suitable steel materials—from steel plates and structural steel to galvanized steel.

Nationwide logistics support reduces transportation expenses and accelerates project timelines. Professional suppliers also offer warehouse handling and unloading solutions to minimize operational costs.

Partnering with a reliable steel supplier reduces risks associated with poor-quality materials, ensures construction progress, and maximizes investment efficiency.

FAQ – Frequently Asked Questions

1. Is imported steel a cost-saving option?

Depending on the project, imported steel may be cheaper if it qualifies for FTA tariff advantages. However, logistics and transportation costs must be evaluated carefully to ensure the total cost stays within budget.

2. How can I determine the amount of steel required for a project?

Consult a structural engineer or use BIM software to calculate the exact steel volume. This prevents over- or under-purchasing and helps control material costs.

3. Is buying steel directly from the mill cheaper?

Generally, direct purchases are less expensive. However, they often require large order quantities and longer delivery times. Quality assurance under recognized standards must also be verified.

Conclusion

Optimizing the selection of steel materials is crucial for reducing construction costs while maintaining quality and durability. Investors should carefully evaluate steel types, sources, and required quantities to achieve the most cost-effective results.

If you need consultation or accurate steel pricing for your project, contact CCN Vietnam—your trusted steel materials distributor committed to quality, punctuality, and competitive pricing.

.png)

-480x320.jpg)