Mô tả

Overview of Steel Base Plates and Steel Fitting Plates

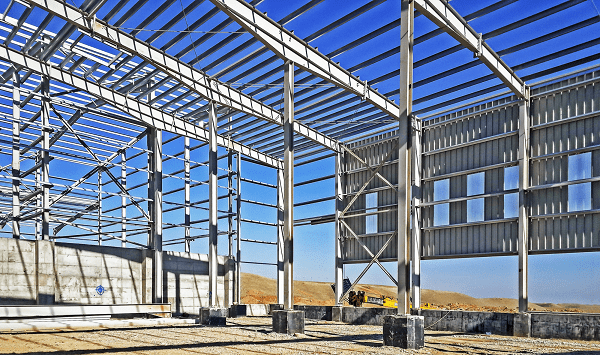

When discussing steel structures, two indispensable materials in any project are steel base plates and steel fitting plates. They play a crucial role in connecting, reinforcing, and ensuring the overall durability of the entire steel framework. Although smaller in size than beams, columns, or purlins, these components significantly influence the stability, safety, and technical integrity of a structure. Understanding their types, standards, and proper selection directly determines long-term construction quality.

Steel base plates and steel fitting plates appear in almost all construction categories—from pre-engineered steel buildings and factories to bridges, roads, and mechanical installation systems. In modern construction trends, these materials are increasingly standardized in dimensions, specifications, load-bearing capacity, and quality inspection.

To master steel structure construction techniques, we must first understand what steel base plates and steel fitting plates are, as they are the key components that create durable connections throughout the system. Selecting the right specifications, standards, and functions ensures maximum load capacity, minimizes construction risks, and enhances structural durability. Starting from the basic definitions, we analyze each type in detail below.

What Are Steel Base Plates?

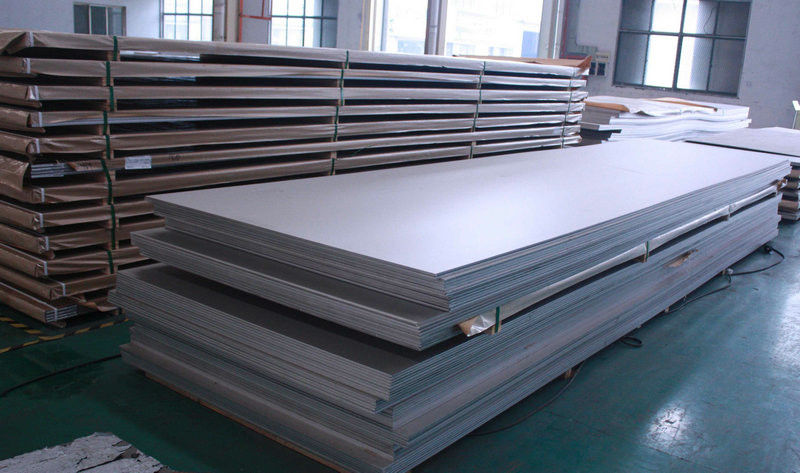

A steel base plate is a square or rectangular steel sheet manufactured from rolled steel plates and processed through laser cutting or CNC punching. In steel structures, the base plate acts as an “anchor point” that connects beams, columns, and purlins or forms joints between steel members. Thanks to its high thickness and excellent load-bearing capacity, it strengthens the steel frame system and ensures each connection meets technical standards.

Connection Function in Steel Structures

Steel base plates are typically used with high-strength bolts to create secure joints at multiple intersection points. During construction, base plates help distribute loads evenly, minimize deformation, and enhance overall safety. They also support faster and more precise installation, as they can be fabricated beforehand in the workshop.

Common Specifications

Steel base plates generally range from 6mm to 20mm in thickness, depending on load requirements and application points. Hole size, spacing, and plate dimensions must follow design drawings and technical standards. The most popular materials include SS400, Q235, and Q345 steel plates.

What Are Steel Fitting Plates (Steel Assembly Plates)?

Steel fitting plates are steel components used to connect, assemble, or secure structural elements in pre-engineered steel buildings and steel construction projects. These components are highly flexible and manufactured according to design drawings to match each specific project. Compared to steel base plates, steel fitting plates come in more diverse shapes due to project-specific customization.

Role in Construction and Pre-Engineered Buildings

In steel construction, fitting plates help secure components in position before bolts are tightened or welds are completed. This ensures greater accuracy, stability, and safety during installation. These plates also speed up construction, enhancing project efficiency.

Advantages in Installation

Steel fitting plates offer several benefits: fast installation, easy removal, flexibility in size adjustments, and reduced structural weight compared to traditional reinforcement methods. When manufactured under proper standards, they ensure precision, durability, and strong load resistance.

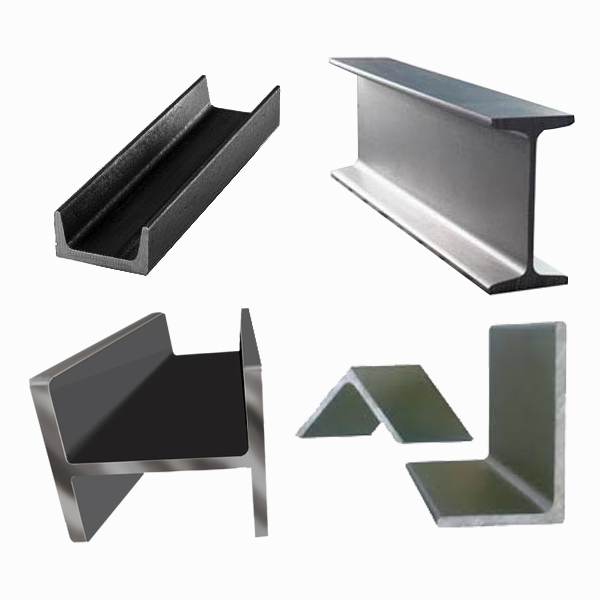

Classification of Steel Base Plates & Steel Fitting Plates

Steel base plates and fitting plates come in many variations to suit diverse applications. Proper classification helps engineers choose the right materials, avoid waste, and meet technical standards.

Perforated vs. Plain Steel Base Plates

Perforated base plates are used for bolt connections requiring high accuracy and strong load-bearing capacity. Plain plates are used for welded joints or positions that do not require bolted connections. Depending on the design, plates may include 2, 4, or more holes for balanced load distribution.

Material-Based Classification: SS400, Q235, Q345, etc.

Steel base plates are categorized by materials such as black steel plates, SS400, Q235, Q345, or high-strength steel. Each type differs in tensile strength, compression resistance, and durability. SS400 and Q345 are the most commonly used due to their excellent machinability and cost efficiency.

Steel Fitting Plates by Standards: ASTM, JIS, TCVN

Fitting plates are typically manufactured per ASTM (USA), JIS (Japan), or TCVN (Vietnam) standards. These standards define tensile strength, hardness, dimensional tolerance, and load-bearing capacity. Compliance with these standards ensures safety and performance in industrial construction.

Manufacturing Process & Technical Standards

Steel base plates and fitting plates undergo strict production processes—from material selection, machining, and inspection to packaging.

Strength, Thickness & Tolerance

Plate thickness typically ranges from 6mm to 20mm depending on application requirements. Dimensional tolerance must be precise to avoid misalignment during installation. Tensile strength and yield strength should meet SS400 or Q345 standards to ensure long-term load resistance.

Load-Bearing Requirements & Welding Standards

Welds must achieve proper penetration with no porosity or cracking. For high-strength bolt connections, holes must be accurately punched without misalignment. These factors directly influence the safety of the entire structure.

Quality Inspection (Tensile Test & Bend Test)

Tensile tests determine strength, while bend tests evaluate deformation resistance. These tests are mandatory for materials used in factories, bridges, and large industrial structures.

Real-World Applications of Steel Base Plates & Steel Fitting Plates

In Pre-Engineered Buildings and Industrial Structures

Base plates connect columns, beams, and purlins to maintain structural stability. Fitting plates support alignment during steel erection, speeding up construction and reducing costs.

In Bridges, Roads & Industrial Factories

These steel components create strong connections between steel sections, helping reduce vibration and support long-term load performance.

In Mechanical Systems & Machinery Installation

Base plates are used for machine mounting, equipment foundations, and pipeline support. Fitting plates enable flexible assembly and adjustment of mechanical systems.

How to Choose the Right Steel Base Plates & Steel Fitting Plates

Choosing the correct steel significantly impacts structural safety. Even minor mistakes can lead to costly repairs or long-term hazards.

Choose Based on Load & Installation Location

Heavier loads require thicker plates and stronger steel grades such as SS400 or Q345.

Choose by Standard Thickness & Steel Grade

Thickness from 10–20mm is suitable for beam-column connections, while lighter loads need only 6–8mm. Steel must adhere to TCVN or international standards such as ASTM or JIS.

Choose Reputable Suppliers

Always select suppliers with CO/CQ certificates and clear testing documents to ensure high-quality steel.

Pricing & Buying Notes for Steel Base Plates and Steel Fitting Plates

Factors Affecting Price

Material grade, thickness, number of holes, production standards, and CNC machining complexity all affect the final price.

How to Avoid Low-Quality Products

Check technical certificates, plate thickness, flatness, weld quality, and cut precision. Low-quality plates often show warping, rough surfaces, or incorrect tolerances.

Trends in Using Steel Base Plates & Steel Fitting Plates

Modern construction increasingly standardizes these components. CNC machining, laser cutting, and automated inspection significantly enhance accuracy, durability, and cost efficiency—aligning with the trend of fast, safe, and optimized construction.

Need pricing or consultation for steel base plates or steel fitting plates?

Contact CCN Vietnam for fast support, transparent pricing, and high-quality certified products!

.png)

-480x320.jpg)