Mô tả

Steel is an essential material in construction and industrial applications, yet it is also highly susceptible to environmental impacts such as moisture, oxidation, and deformation. Without proper storage, steel can lose its structural quality, pose safety risks to projects, and increase repair and replacement costs.

CCN Vietnam shares the most effective warehouse steel storage principles to help businesses, contractors, and investors ensure steel remains in optimal condition before being put into use.

1. Effects of Environmental Conditions on Steel

Steel is a high–strength metal material, but it is easily affected by environmental factors if not stored correctly. High humidity accelerates oxidation, causing rust formation and reducing the mechanical properties of steel over time.

Fluctuating temperatures can cause expansion and contraction, leading to warping or distortion, especially in steel sections, steel pipes, or steel coils. Direct contact with soil or rainwater increases the rate of surface corrosion, reducing durability and shortening product lifespan.

Therefore, proper warehouse storage is essential for all distributors and suppliers of industrial steel and construction steel.

2. General Principles for Storing Steel

A standard steel warehouse should be well–ventilated, covered, and protected from direct sunlight, moisture, and rain exposure. This helps maintain steel stability before it is used in construction or manufacturing.

Steel should be stacked on elevated racks or wooden supports to prevent moisture absorption from the ground. If stored outdoors temporarily, steel must be tightly covered to minimize oxidation.

Humidity control through ventilation systems or dehumidifiers is especially important for hot–rolled steel, cold–rolled steel, and steel coils.

3. Storage Methods for Different Types of Steel

Hot–rolled and Cold–rolled Steel Plates

Steel plates should be stacked in batches with padding layers between sheets to prevent friction and surface scratches. Applying a light anti–rust oil coating reduces oxidation risk, particularly in high–humidity environments or long–term storage.

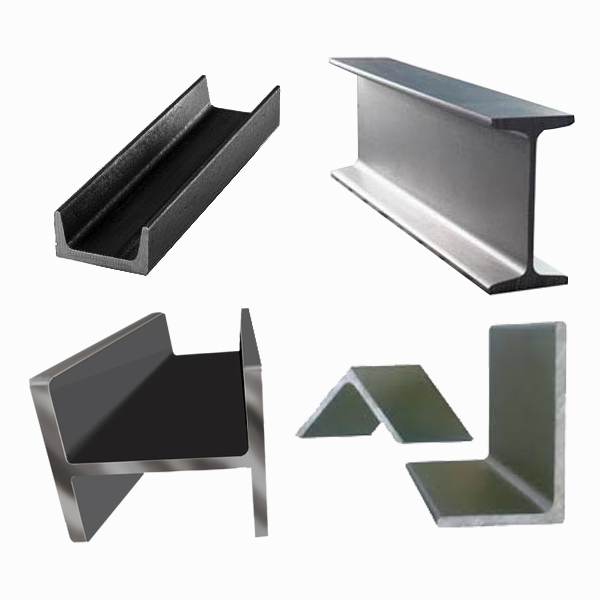

H, I, and U Steel Sections

Steel sections should be stored horizontally on stable racks to maintain straightness and prevent bending. Securing bundles ensures steel remains aligned, especially during handling and warehouse movement.

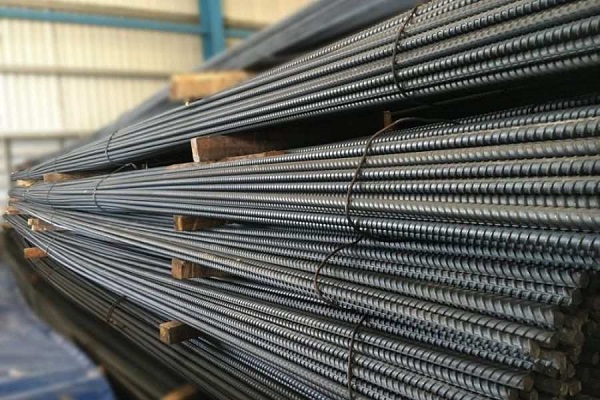

Seamless and Welded Steel Pipes

Steel pipes should have both ends sealed to prevent dust, moisture, and debris from entering the interior, maintaining quality and industrial cleanliness. Pipes should be stacked in circular bundles with blocking bars to prevent rolling and ensure safety.

Hot–rolled Steel Coils and Galvanized Steel

Steel coils must be placed on wooden supports and should not be stored upright due to risk of deformation. Galvanized steel must be kept dry and away from corrosive chemicals to preserve the protective zinc coating.

4. Common Mistakes in Steel Storage

– Storing steel directly on warehouse floors, causing moisture absorption and rust

– Leaving steel uncovered outdoors, leading to surface oxidation

– Stacking steel too high, causing bending and misalignment

– Skipping routine inspections, allowing rust to progress unnoticed

5. Standard Steel Storage Procedure

Upon receiving steel, CO–CQ certificates must be verified and surface conditions inspected to ensure compliance. Steel should then be classified by type, such as plates, sections, pipes, or coils, and stored accordingly.

Bi–weekly inspections help detect early signs of rust or deformation. If oxidation occurs, surfaces should be cleaned and re–oiled, and covers replaced if damaged. When releasing steel from storage, FIFO (first in – first out) should be applied to prevent prolonged inventory aging.

FAQ – Frequently Asked Questions

1. Can steel with light rust still be used?

Yes, if rust is only superficial and has been cleaned properly, but it is not recommended for high–load structural applications.

2. Does galvanized steel require special storage?

Yes. Although it resists rust better, galvanized steel must still avoid moisture and chemicals that may damage the coating.

3. Can steel be stored outdoors for long periods?

Only temporarily, for a few days at most, and it must be fully covered to prevent oxidation.

Proper steel storage not only maintains material quality, but also helps businesses reduce costs and prevent structural risks. For better assurance, steel should be sourced from reputable industrial steel suppliers with professional warehousing and logistics capabilities.

Contact CCN Vietnam - an authorized steel distributor with certified storage facilities and nationwide delivery support - to receive today’s steel pricing and optimal storage solutions.

.png)

-480x320.jpg)