What is galvanized steel?

You could hear of galvanized steel a lot nowadays. So, what is this type of steel?

I. What is galvanizing?

Galvanizing is the process of applying a protective layer of zinc to steel or iron to prevent rust. The most common method is hot-dip galvanizing, in which parts are immersed in a bath of hot molten zinc.

II. What is galvanized steel?

Galvanized steel (English name: Galvanized steel) is a steel material covered with an outer layer of zinc to help it avoid the effects of the surrounding environment. Thereby limiting the possibility of rust, oxidation and corrosion, increasing the durability and longevity of the product. Galvanized steel also increases aesthetics thanks to a diverse system of plating colors including: white, blue, yellow, black, and rainbow colors.

Galvanized steel sheet rolls

III. Methods of galvanizing steel

To galvanize steel, there are three commonly used methods today: cold galvanizing, hot-dip galvanizing and electrolytic galvanizing.

- Cold galvanizing: is done by coating the steel surface with a layer of liquid zinc at normal ambient temperature similar to painting. The advantage of this method is that it saves effort, the zinc coating has good adhesion, is cheap, and does not affect the shape and structure of the steel.

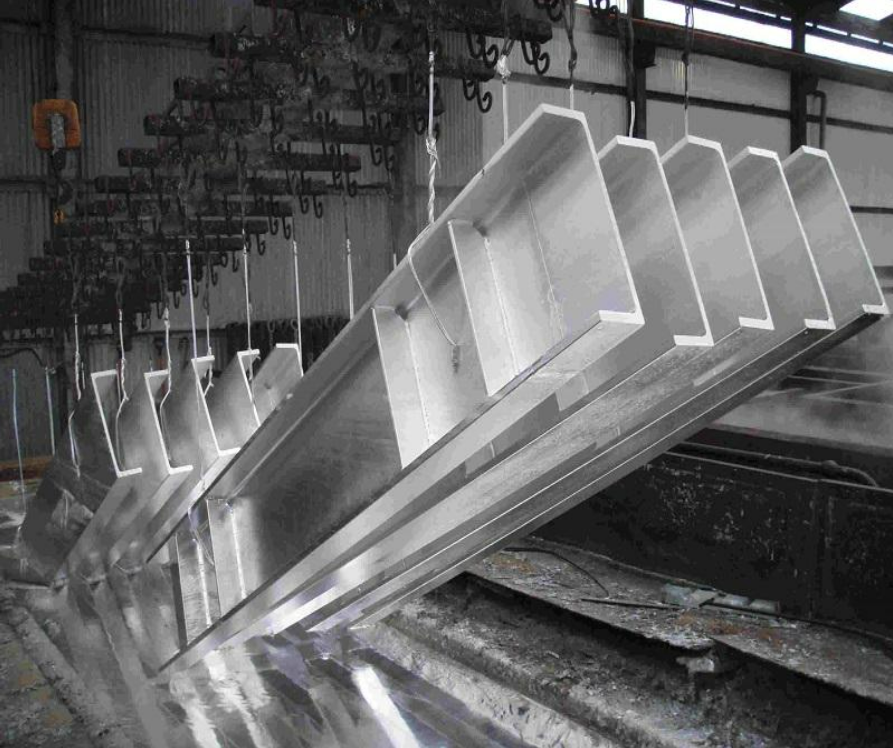

- Hot-dip galvanizing: is a galvanizing method by dipping steel materials into a bath of molten zinc. This method has the advantage of simple implementation, the zinc layer adheres evenly to the entire product surface, high durability, good rust resistance, smooth and aesthetic material surface.

- Electrolytic zinc plating: is a method of directly spraying plating chemicals onto the surface of the product using spraying or many other equipment. Their advantage is high adhesion, thin and smooth zinc layer, so suitable for machine parts.

Depending on the usage environment and customer needs, the production unit will apply appropriate steel galvanizing methods.

Galvanized steel sheet rolls

IV. How does the galvanizing process take place?

Steel can be hot-dip galvanized or electrolytically galvanized. The hot-dip galvanizing method is the most commonly used. The implementation process includes the following 4 basic steps:

Step 1: Clean the metal surface

After being made, steel can adhere to impurities, oil, and dirt during storage and transportation, so it needs to be cleaned for the zinc layer to have the best adhesion.

The material will be soaked in the degreasing solution for 10 - 15 minutes. Then continue soaking in HCl Acid solution with a concentration of 8 - 15% to remove rust. In addition, electrochemical methods can be used to separate grease from steel surfaces.

Step 2: Embed the flux

After cleaning, the steel is dipped into the flux for about 3 - 20 seconds at normal temperature to completely remove iron ions and oxide plaque formed on the surface, while creating a protective coating that prevents oxidation. The steel is then dried to prepare for the plating process.

Step 3: Hot-dip galvanizing

This is the most important step in the galvanizing process to create a zinc coating on the steel surface.

Completely dip the steel material into the galvanizing tank. Molten zinc will wet the steel surface and a galvanizing reaction will occur. When the temperature in the galvanizing bath reaches the melting point (454آ°C - 465آ°C), the galvanizing reaction is completed.

.png)

Detailed hot-dip galvanizing process

Completing the galvanizing process, perform slag scraping on the molten surface and combine vibration to remove excess residue. Then dip the product into chromate solution to create a protective layer for the surface.

Step 4: Cool and check the finished product

The product is cooled in an overflow water tank to make the surface shiny and beautiful. Technicians observe the surface and check the thickness of the plating layer using a specialized measuring machine to make sure the finished product meets technical requirements and standards.

The galvanizing process needs to comply with technical requirements to produce the best finished product

آ

Advantages and characteristics of Galvanized steel

The zinc plating process gives steel materials many outstanding advantages including:

- Low cost: Production costs for the steel galvanizing process are lower than using other surface protection coatings. Therefore, the price of this material is not high. That is why galvanized steel becomes the top choice for large-scale projects.

- Relatively good durability: The zinc coating helps the product resist corrosion and rust from the environment, limits the chemical reaction of chemicals with the inner steel layer, increasing the life and durability of the steel. material. According to research, galvanized steel can achieve a durability of over 50 years in favorable environments and 20-25 years in harsh environments such as industrial parks and coastal areas.

- High aesthetics: Compared to conventional steel materials, galvanized steel has a shiny surface and is more aesthetically pleasing. They also have many colors for customers to choose from such as bright white, rainbow yellow, blue, yellow, black...

- Save on maintenance costs: Galvanized steel products are highly durable and have a longer lifespan, so you can save on maintenance costs during use.

آ

Application of galvanized steel

The nature of galvanized steel is steel, so they inherently have very high durability. After being coated with zinc, they will be able to resist external environmental influences such as rain, wind, sun, corrosion, humidity, etc., helping to increase the product's lifespan.

Currently, galvanized steel is used in many different fields and industries. Some popular applications include:

- Deck floor application to replace floor formwork.

- Making ventilation pipes for apartments, high-rise buildings, shopping centers, factories, etc.

- Production of purlins.

- Production of box pipes, water supply and drainage pipes, oil and gas pipes, or to make vehicle parts...

- Producing civil products such as small boats, iron boxes, storage boxes, water buckets, etc.

With the above great advantages, galvanized steel is widely used in life and many manufacturing industries.

Most industries that apply galvanizing steel need to use a large amount of iron and steel, but are susceptible to rust and oxidation under the impact of the environment. Typical examples include chemical industry, pulp and paper, traffic equipment manufacturing, communications, lighting and transportation, etc.

Some outstanding galvanized steel products include: Deck floors, ventilation pipes, purlins, water supply and drainage pipes, boats, drums,...

Used as pipelines for oil, clean water, and gas

Floor drain plate

Galvanized steel pipe

Galvanized steel used for Deck flooring

آ

.png)

-480x320.jpg)

Write a comment