Tole Zam

1. What is Tole Zam?

ZAM steel (Tole ZAM) is an alloy of steel with zinc - aluminum - mages developed in accordance with the new product line of the 21st century. The coating of ZAM steel is plated with Aluminum, Mage with an exact content of 6% Aluminum. and 3% Mage to increase product durability. Therefore, ZAM Steel is a type of steel that has superior wear resistance compared to galvanized steel and Galfan steel.

ZAM is an abbreviation from the first letter of the materials Zinc (Zn), Aluminum (Al) and Mage (Mg).

2. Parameters of Ton RAM

– Thickness: Zam steel usually has thicknesses of 0.25mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm. And we can produce Zam corrugated iron sheets with different thicknesses depending on customer requirements.

– Width: Zam steel has widths from 750mm to 1250mm.

– Length: Zam corrugated iron has length depending on customer requirements, can be cut to required size.

– Uses: Zam corrugated iron is widely used in the construction and mechanical industries, especially in projects that require high durability and good corrosion resistance and waterproofing. Zam steel is also used in the production of automobiles, home appliances and electronic equipment.

– Wear resistance: Zam steel has superior wear resistance compared to other materials, especially in environments with high humidity or exposure to corrosive substances.

– Durability: Zam steel has high durability, can withstand pressure, traction and strong winds.

– Color: Zam steel has a shiny color that retains its color for a long time.

3. Structure and characteristics of Corrugated RAM

3.1. Structure of Ton Zam

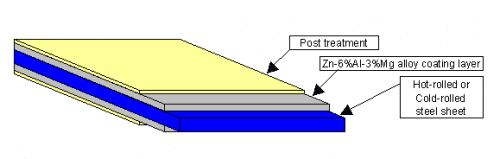

Zam steel is created by combining the main materials steel, zinc, aluminum and magnesium. The structure of Ton Zam includes the following layers:

– Protection layer: Zam steel is protected by a zinc aluminum magnesium (ZAM) coating with Al and Mg content of 6% and 3% respectively. This plating helps Zam steel resist corrosion and minimize the impact of external factors such as rain, wind, and sun.

– Zinc layer: The zinc layer is located below the protective layer, helping Zam corrugated iron resist corrosion and increase durability.

– Steel layer: The steel layer is located below the protective layer, responsible for bearing force and preventing deformation.

With this special structure, Zam steel is more wear-resistant and durable than other conventional steels.

3.2. Characteristics of Ton Zam

Zam Steel is researched and developed to improve the corrosion resistance of steel materials in environments with many factors that corrode steel. Accordingly, Zam Steel is covered by a thinner coating but is able to protect the steel material better than conventional paint. Because this coating is thinner, investment costs can be saved. In addition, Zam Steel also has many outstanding advantages compared to other types of protective coatings for steel materials:

– Longer lifespan

– Lower maintenance costs

– The weight of the coating is lower than that of other metals

- Cut the cost

- Environmental friendliness.

4. Uses and applications of Corrugated RAM

4.1. Uses of Ton zam

– Zam steel has high wear resistance, so it is used to produce surfaces that require high wear resistance such as pump shafts, gears and other moving machine parts.

– It also has good anti-corrosion properties, so it is used to produce chemical storage tanks, water tanks, bridge structures and oil and gas bridges, wastewater treatment systems and other resistant parts. Corrosion in the chemical industry.

– Zam steel also has high bearing capacity, so it is used to produce bridge structures, oil and gas pipelines, factory structures, beam and column structures, high-rise building structures and assemblies. Other structural parts in construction and industry.

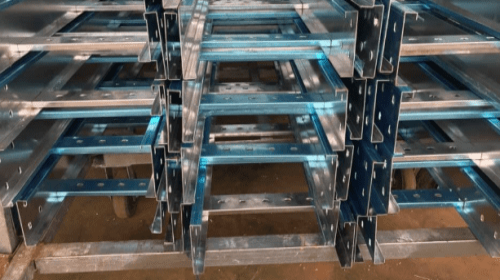

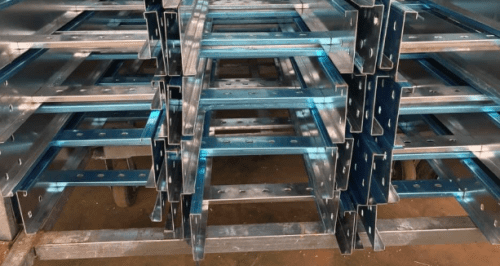

Cable ladder made from Zam corrugated iron

4.2. Application of Zam Steel

– Zam steel can be used to produce parts and structures in the shipbuilding industry, including ship footbeds, shipboard structures and other parts.

– It is also used to produce highly wear-resistant surfaces in fabrication equipment in the automotive and electronics manufacturing industries.

– Zam steel has good corrosion resistance, so it can also be used to produce storage tanks and chemical processing equipment in the chemical industry.

– ZAM steel is used as a structural material for housing in construction, as a wave spreading material, as a soundproofing material in electrical applications, as a material in air conditioning, containers, cable trays, traffic signals, power supply materials, electrical cabinets, cable ladders, agricultural materials, greenhouse materials and some agricultural equipment.

Cable ladder made from Zam

Cable ladder made from Zam

5. Units that import and sell RAM sheets

- Phuong Anh

- SMC

- Chung Thuy (Thach That)

- …

(Learn about the import source from Japan, currently learning more about the market, importers and suppliers)

.png)

-480x320.jpg)

Write a comment