Electro galvanized steel (GA-EG)

Electro galvanized Steel is a metal material that has many applications in life.

The essence of electroplating i.e. the application of an electrolytic cell in which a thin layer of metal is deposited on a conductive surface. During the electroplating process, the metal material to be plated is attached to the cathode, and the plated metal is attached to the anode of the power source in the dielectric solution. The anode of the power source will attract e- electrons during the oxidation process and release positive metal ions. Under the effect of electrostatic force, these positive ions will move to the cathode, where they receive e- in return. The redox process forms a metal layer on the surface of the plated object. The thickness of the plating layer is proportional to the current intensity of the source and the plating time.

Electro galvanized steel types

There are two types of electro galvanized steel: Electro Galvanized Steel (EGI) and Galvannealed Steel Sheet (GA). Each type has its own standards and applications. You can check below information for more details:

1. Electro Galvanized Steel

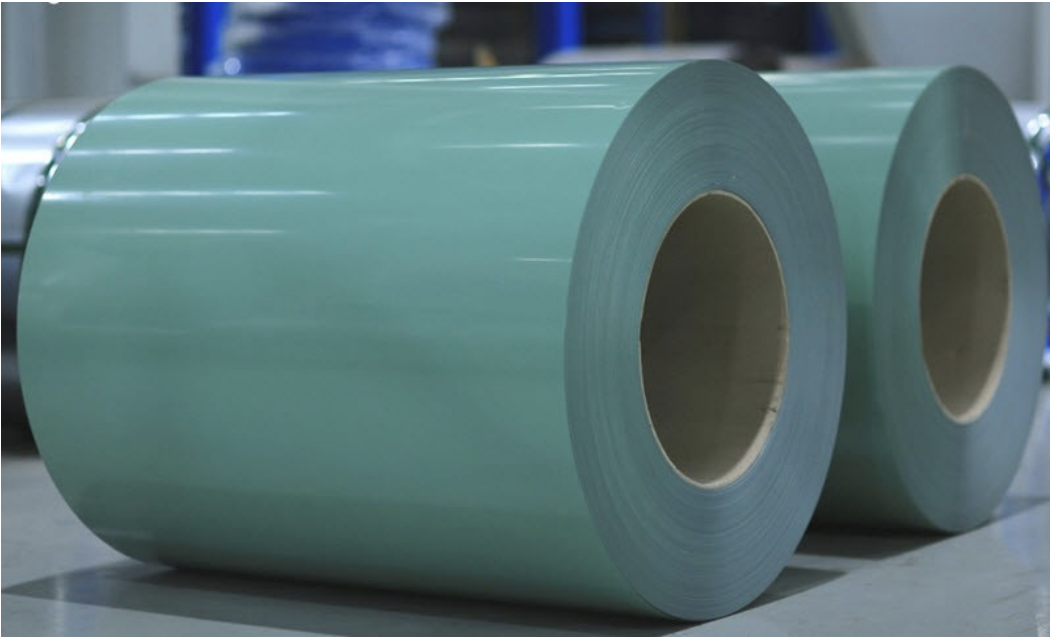

Electro Galvanized Steel (EGI) is a type of steel produced by electroplating technology from cold rolled steel to increase corrosion resistance, but has less zinc than hot dipped galvanized steel (GI). The plating is very flat, has a clean surface, and maintains the mechanical properties of CR because the galvanizing is done at low temperatures.

Also plated with different alloy compositions, however, this product is coated with an "anti-finger" layer that can withstand moisture, stains, grease, and dust from the external environment. . Often used in the production of boxes, frames, and supports for electrical circuit boards, civil and industrial electronics. This type of product is not used for details, the product needs to be re-plated after complete shaping.

Seen with the naked eye, the product is blue in color and has a bright shine. Especially when you use your hand to wipe the surface, it does not leave fingerprints on the product. Unlike the GL type, which also has the same anti-stick protection feature, but has poor crushing and deepening properties.

|

Application |

Standard |

Usage |

|

Commercial properties |

JIS G3313 SECC |

Furniture, computer CPU cases, electronics, electrical equipment |

|

Normal stamping properties |

JIS G3313 SECD |

Automobile |

|

Deep stamping properties |

JIS G3313 SECE |

Automobile |

2. Galvannealed Steel Sheet

Galvannealed Steel Sheet (GA) is produced by secondly heating the plating layers to coat zinc and metal materials on the surface. To the naked eye, the product is ash gray (not coated with oil) or dark gray (coated with oil) and does not reflect light.

From cold rolled steel products, the steel is processed and plated by electrolysis method with the main coating component being zinc. Unlike galvanized steel sheet products, only the final product can be detailed through production and shaping. Electroplated steel sheet is used for details that need to be painted after complete shaping. Because it is also plated with zinc, it is highly resistant to environmental corrosion.

Seen with the naked eye, the product is ash gray, non-reflective (unlike hot-rolled steel that has been soaked and de-rusted (PO) for a certain amount of light reflection).

Finished products have a thickness of 0.30 - 4.50mm depending on the market used. Roll weight from 4000 - 25,000 KG.

| Common grade |

SGCC, SGHC, A653, A792,… |

|

Standard |

JIS G3302, ASTM A653/CQ, DX51Z/Q195/Q215/Q235,… |

|

Thickness |

0.4mm -> 3.00mm |

|

Width |

1.000mm, 1.200mm, 1.219mm, 1.250mm, khác (từ 20mm -> 1600mm) |

|

Length |

2.000mm, 2.440mm, 2.500mm hoặc dạng cuộn |

Application: Used to produce round pipes, square pipes, rectangular boxes, purlins, electrical cabinets, mechanical cabinets, motorbike and car parts...

.png)

Write a comment